FOOD AND BEVERAGE

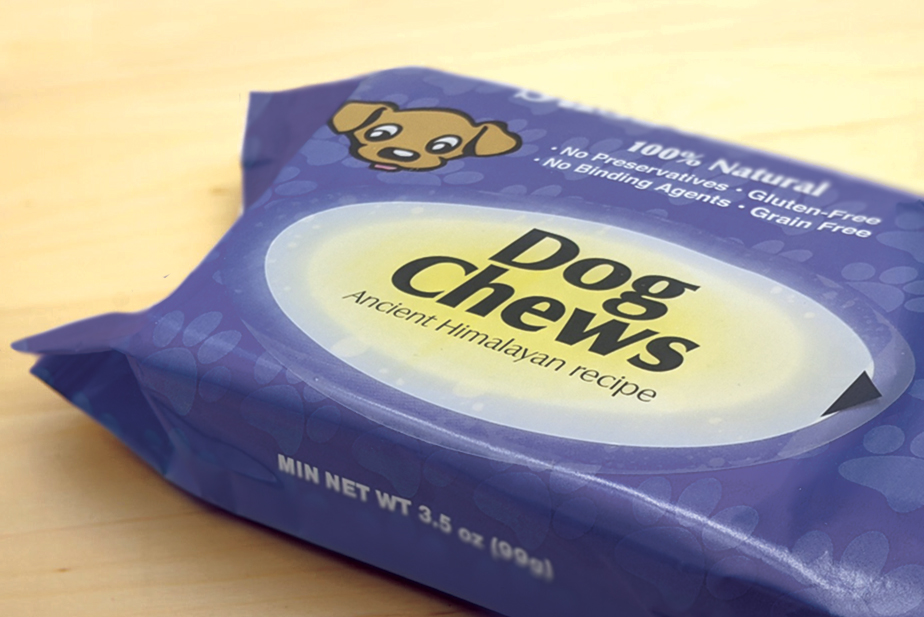

When your brand is in the hands of the Lauterbach Group, you can be assured of our relentless commitment to food safety practices, so you can deliver high quality, reliable and safe food products to your clients. Our pressure sensitive labels conform to an array of packaging types including glass, hard and soft plastics, metal, paper and corrugated substrates – ridged, semi-ridged and conformable containers. Our labels, teamed with The OmniMark™ Management System provide designs and constructions that will create eye catching appeal on the store shelf.