The Evolution of Labeling Technology: Embracing Linerless Direct Thermal Labels

In the dynamic world of packaging and labeling, the quest for efficiency, sustainability, and cost-effectiveness is ceaseless. A significant breakthrough in this pursuit is the adoption of linerless direct thermal labels. These innovative labels are revolutionizing the industry, offering an array of benefits that address environmental concerns, boost productivity, and reduce operational costs. In this blog, we delve into the significance of linerless direct thermal labels and how they stand as a testament to the evolution of labeling technology.

What Are Linerless Direct Thermal Labels?

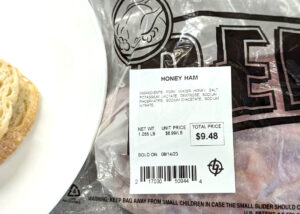

Linerless direct thermal labels are a type of label that comes without the traditional backing paper, or liner, that is commonly found on standard labels. These labels are coated with a heat-sensitive layer and are printed through specific Linerless Direct Thermal printers that activate the coating to produce the image. The absence of a liner means these labels are not only more environmentally friendly but also more efficient in various labeling processes.

What are the advantages of Linerless Direct Thermal Labels?

Environmental Sustainability:

The most pronounced benefit of linerless labels is their positive impact on the environment. Traditional labels generate liner waste, which often ends up in landfills. Linerless labels eliminate this waste, significantly reducing the environmental footprint of labeling processes. By adopting these labels, businesses can take a substantial step towards sustainability and eco-friendly practices.

Increased Productivity:

Increased Productivity:

Linerless labels offer a longer roll length compared to traditional lined labels, which means fewer roll changes and reduced downtime. This increase in operational efficiency can lead to a significant boost in productivity, especially in industries where labeling is a high-volume, continuous process.

Cost-Effective:

Eliminating the liner also means reducing material costs. Moreover, with increased productivity and reduced waste management costs (no liners to dispose of), businesses can expect a noticeable decrease in overall operational expenses. A small investment in a Linerless Direct Thermal Printer will increase your ability to reduce costs.

Versatility and Space Saving:

Linerless labels can be cut to any length, offering versatility for various products and packaging types. This adaptability ensures that businesses don’t overuse materials and can cater to different product sizes without the need for multiple label sizes. Additionally, linerless rolls are more compact, saving valuable storage space.

Safety and Cleanliness:

In environments where cleanliness and safety are paramount, linerless labels are a boon. They leave behind no liner waste, reducing the risk of slips and falls in the workplace and contributing to a cleaner, more organized environment.

The Impact on Industries

Various industries are reaping the benefits of switching to linerless direct thermal labels. In the food service industry, for instance, the ease of variable length printing allows for clear and precise labeling of ingredients, expiration dates, and barcodes, all while adhering to strict hygiene standards. In logistics and retail, the efficiency, and space-saving characteristics  of linerless labels streamline operations and inventory management, proving that this innovation is not just a trend but a substantial operational upgrade.

of linerless labels streamline operations and inventory management, proving that this innovation is not just a trend but a substantial operational upgrade.

Embracing the Change

Transitioning to linerless direct thermal labels represents a forward-thinking approach to business operations, aligning with global trends of sustainability and efficiency. However, it requires an initial investment in compatible printing technology and a willingness to adapt to new processes. The long-term benefits, from cost savings to environmental impact, present a compelling case for businesses to embrace this change.

In conclusion, linerless direct thermal labels are more than just an alternative to traditional labels; they are a significant step forward in the labeling industry. By offering an eco-friendly, efficient, and versatile solution, these labels are setting a new standard, prompting businesses to rethink their labeling strategies and adopt a more sustainable, productive future. As we continue to navigate the complexities of modern business operations, innovations like linerless direct thermal labels lead the way in creating solutions that are beneficial for businesses, consumers, and the planet alike.